Whether you are starting a business for the first time or like expanding your business, Alibaba would be the first platform that comes to mind for many buyers. With millions of product listings, this platform has become the go-to for sourcing a wide variety of goods. With thousands of manufacturers, it’s easy to be unsure where to start.

In Alibaba’s huge manufacturer system, it is also a big challenge to find a manufacturer that can meet your needs. In this guide, hands-on steps will be provided to help you find a reliable manufacturer.

Are there only manufacturers on Alibaba?

No, there are not only manufacturers on Alibaba, but also a very large number of trading companies. Trading companies usually have strong foreign language skills and cross-cultural communication skills, which enable them to convey customer needs more clearly and avoid misunderstandings in communication.

They can help foreign buyers better understand product characteristics, contract terms, quality requirements, etc. to ensure a smooth transaction. Trading companies often have a deep understanding of the local market and are able to provide foreign clients with more appropriate negotiation strategies and business advice to ensure that the agreements reached between the two parties are enforceable.

China has a large number of small and medium-sized manufacturing enterprises (SMEs), which often have high production flexibility and customization capabilities. However, these small businesses may have limited production capacity, quality control, and scale, and many customers have a need for small lot sizes or customized products.

In China, many manufacturers often require high minimum order quantities (MOQ), which can become a threshold for some small or start-up businesses. Still, there will be buyers who want to find factories on Alibaba, and the following aspects can guide you in the right direction.

Ways to find actual manufacturers on Alibaba

1. Manufacturers based on geographic concentration of industry

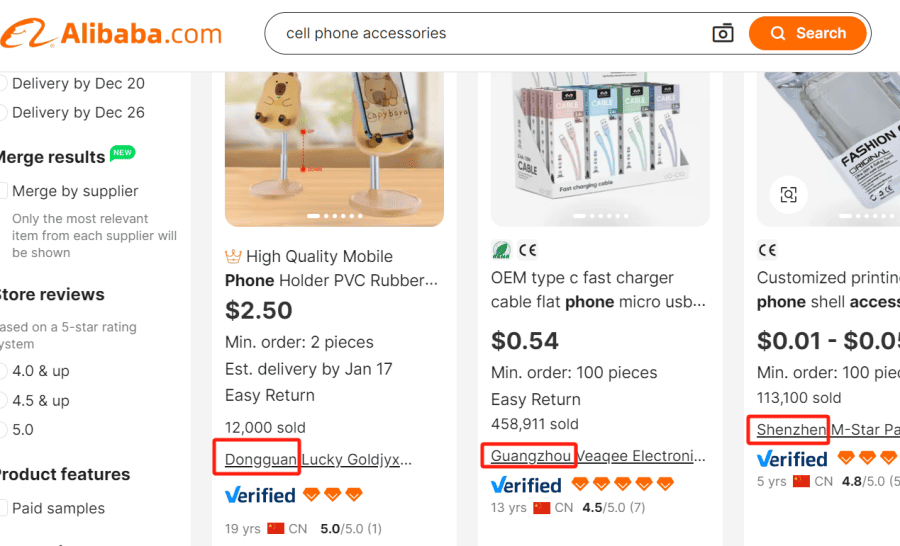

A very good way to find actual manufacturers is from the perspective of geographically concentrated industries. There are several industrial concentration areas in China, and most of the manufacturers in these areas have the scale and production capacity. By analyzing a supplier’s geographic location, it can help Quick Read determine if it is a manufacturer.

Many regions in China have developed industry-specific agglomeration effects due to their unique resource, technological or historical advantages. Example:

- Guangdong Province (especially Shenzhen and Dongguan): This is a major manufacturing center for electronics, consumer goods and toys. Most suppliers of electronic components, cell phone accessories, toys, etc. are likely to be actual manufacturers rather than intermediaries.

- Zhejiang Province (especially Wenzhou and Yiwu): Wenzhou is dominated by footwear, leather products and machinery, while Yiwu is an important production base for small commodities and jewelry. If your products are involved in these areas, choosing suppliers located in these places usually increases the chances of finding real manufacturers.

- Jiangsu Province (e.g. Suzhou, Changzhou): With a focus on high-end machinery and equipment, textiles and auto parts, many manufacturers are located here.

2. Judge whether it is a manufacturer according to the head of the enterprise

A business letterhead (i.e., company name) is a visual way to determine whether a supplier is a manufacturer. While some trading companies will cleverly name themselves to give the false impression that they are manufacturers, a true manufacturer will usually reflect the nature of its production or the industry sector it specializes in in its company name.

Key points to look for in a company name

Includes the words “manufacturing”, “production”, “factory”: If the supplier’s company name contains the words “manufacturing”, “production”, “factory” or other production-related words, this is usually a strong signal that the company has its own independent production facilities. ”, “manufacturing”, “production”, “factory”, or other production-related words in the supplier’s company name, this is usually a strong signal that the company has its own separate production facility. For example, names such as “XX Electronics Manufacturing Co.” and “YY Furniture Factory” generally signify that the supplier is an actual manufacturer.

Industry Focus: Some manufacturers will directly indicate in their company name that they specialize in a particular industry sector, such as “XX Machinery & Equipment Manufacturing Co. These names usually reflect specialized manufacturing capabilities focused on a particular industry.

3. Number of product categories in the online store

Linkage between product range and production capacity

Specialization: True manufacturers tend to offer a range of related products that are often part of the same type of line. For example, certain manufacturers specialize in electronics and may have a range of products such as cell phone accessories, headphones, Bluetooth stereos, etc., rather than being limited to a single commodity.Such suppliers can usually demonstrate strong production technology and supply chain management capabilities, indicating that they have sufficient production lines and equipment to support large-scale production.

Diverse customization services: A manufacturer with a wide range of product categories can often offer customization services to its customers. If a supplier’s store displays multiple styles of products with different functions and offers flexible customization options (e.g., size, color, and function customization), it is likely that the supplier has strong production capacity and flexibility to meet the needs of different industries or customers.

4.Video call to view manufacturer's production environment: direct verification of production facilities

A few of the above methods can be used to initially determine if it is a manufacturer. The most effective way to determine if it is a manufacturer is by communicating with the manufacturer on a video phone call and directly viewing their production environment.

- Visualize the production environment: Through video calls, buyers can directly view the inside of the supplier’s factory, such as the production plant, the equipment of the production line, and the operation of the workers. This is more persuasive than simply viewing pictures or text descriptions.

- Checking the production process: A video call can also give buyers an overview of the entire production process, including every step of the process, from sourcing raw materials to shipping the finished product. Genuine manufacturers usually have strict production processes and quality management systems in place, whereas trading companies usually do not have such facilities.

- Check the size of the factory and equipment: a real manufacturer usually has several production workshops and a complete set of production equipment, the type and size of the equipment can directly reflect the production capacity of the factory. Buyers can ask suppliers to show the size of each production line, the number of workers and their workflow in a video call.

Practical Tips for Finding the Best Manufacturers on Alibaba

1. Discuss the product with the manufacturer to assess their specialized comprehensive capabilities

Communicating with a manufacturer is more than simply asking for prices and delivery dates; it is an opportunity to assess their professional competence and overall quality. Through in-depth conversations, you can learn about their technical level, production capacity, quality control processes, as well as their responsiveness and problem-solving abilities.

For example, when customizing a piece of furniture with intricate designs and features, I took the initiative to ask the manufacturer the following questions:

- Production process: We wanted a product that was not only beautiful, but also highly durable. We asked about the materials and production processes they use to ensure that the furniture lasts. For example, are moisture and corrosion resistant treatments used? Does it meet our environmental standards?

- Design feasibility: We discussed the unique design of the product and asked if it could be produced according to the design drawings we gave. Is there any similar production experience? If not, did they provide optimization advice?

This kind of communication can help you assess whether the manufacturer is sufficiently specialized. If their answers are not only technical, but also able to suggest specific improvements, it shows that they not only understand the manufacturing process, but also have a certain level of technical competence and industry experience.

Understand their capacity through questions

In addition to detailed product requirements, you can also learn about their production capabilities through dialog. For example:

Delivery lead time: ask if their production lead time meets your needs.

Quality control: find out how they carry out quality control, whether they have a specialized QC team, whether there is a quality inspection link in the production process, and so on.

After-sales service: Very often, the after-sales service provided by the manufacturer is directly related to the long-term cooperation. We have communicated with the manufacturer to confirm their response time and solutions when there are problems with their products.

2.Compare prices and samples from multiple manufacturers, place test orders

Once you have initially culled a few manufacturers, the next step is to compare prices and sample tests. Through price and sample testing, you can get a more intuitive understanding of the manufacturer’s capabilities and product quality. Especially on an international platform like Alibaba, where competition among merchants is fierce, a balance between price and quality is critical.

Practical tips: price comparison and attention to detail

- Components of the offer: Some suppliers quoted low prices but did not specify transportation costs and customs duties. We need to confirm these costs separately from other suppliers so as to avoid additional expenses at a later stage.

- Production lead time and minimum order quantity (MOQ): Some manufacturers have short production lead time but high minimum order quantity, while others can offer small batch production according to our needs, which enables us to conduct market tests before making decisions.

Practical Tips: Sample Testing and Quality Verification

- After getting quotes from different manufacturers, I chose to request for samples from each supplier. This step helped us to get a very clear picture of the quality of the product.For example, we made the same sample request from three different lamp suppliers. While each manufacturer provided products that met our basic needs, the differences in sample quality were clear:

- Materials and workmanship: Some luminaire suppliers used materials that did not meet our standards, resulting in samples that were rough to the touch and unstable luminaires. Other suppliers used higher quality materials with a feel and appearance that met our expectations.

- Packaging: We pay special attention to the details of packaging because it directly affects the safety of the product during transportation. Some suppliers had simple packaging that was easily damaged, while others used multi-layer packaging and cushioning materials to ensure that the products would not be damaged during transportation.

Test orders: verifying the feasibility of long-term cooperation

After sample testing, when you decide to place a test order for a small batch with a selected manufacturer. The purpose of this order was to check product consistency and delivery reliability in mass production.

- Production Consistency: We are particularly concerned about whether the product after mass production is consistent with the sample. Many manufacturers can achieve good product consistency in small batches, but quality may fluctuate in mass production.

Delivery punctuality: - Delivery punctuality: Delivery time is a very important factor. During the production order process, we track the delivery progress to ensure that the manufacturer delivers within the agreed time. If there are delays, the reasons are promptly understood and solutions are proposed.

You import products from China, Goodcan VS Alibaba Advantages

Finding a manufacturer on alibba is easy, but finding a responsible, high quality and service-oriented manufacturer is not. An agency service provider like Goodcan with extensive sourcing experience and a focus on service can help you solve these problems. Their advantages include:

1. End-to-end service: from sourcing to delivery

One of Goodcan’s key strengths is that it offers a complete end-to-end sourcing service, which means that organizations don’t just get a supplier, they get a partner that handles everything from sourcing, quality control and negotiation to logistics and delivery.

2. Vendor review and quality control

Goodcan is a specialized procurement services company that works directly with trusted, vetted suppliers and conducts on-site audits and quality control checks.Goodcan’s team builds relationships with these suppliers to ensure that products meet your quality standards before they are shipped. They provide more hands-on oversight, reducing the risks involved in sourcing from unfamiliar or unverified suppliers.

3. Risk mitigation and dispute resolution

Goodcan offers dispute resolution as part of their service, providing more effective and timely solutions. As they manage relationships with suppliers, they have greater leverage and can directly mediate any issues that arise. If there is a problem with an order, Goodcan can step in quickly and resolve the issue, ensuring that your business does not suffer from product defects, delays or quality issues.

More questions are frequently asked by clients

How do I find the manufacturer of a particular product?

In addition to using the search function within the platform, another effective way to directly locate the industrial parks of the corresponding products is through the search method of industrial concentration areas. Many products have industrial clusters with centralized production in certain regions of China.

How do I find manufacturers outside of Alibaba?

Goodcan can improve the efficiency of finding quality manufacturers and reduce the risk of collaboration.They have a network of collaborating manufacturers, most of which can no longer be found on Alibba.