Before mass production, make sure that all details are mutually agreed upon with your Chinese supplier to ensure a smooth production process and avoid unnecessary rework or delays due to unclear subsequent communication.

In this article, we will introduce the key points that should be confirmed with your Chinese supplier before the official start of production, to help you fulfill every aspect of your order more smoothly.

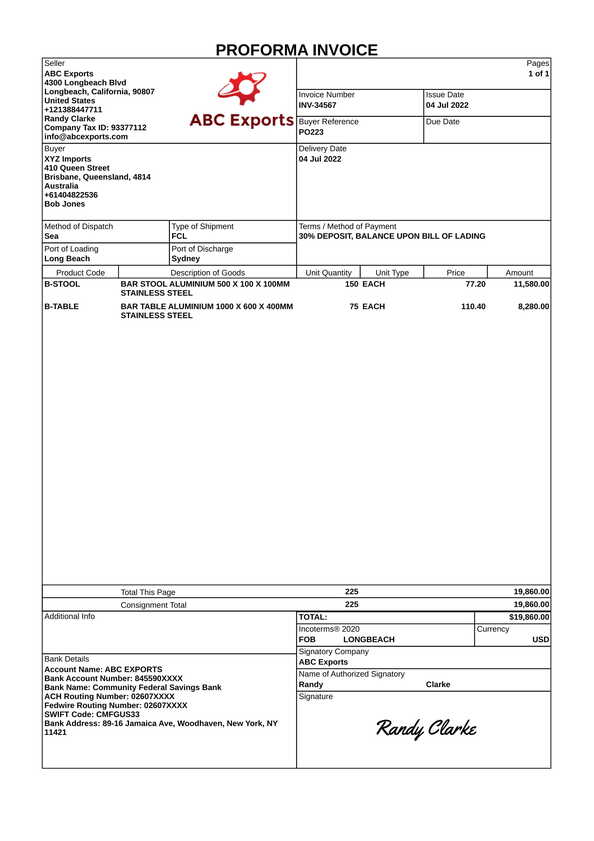

1. Confirmation of pro forma invoice

Before formal production, you should confirm with the supplier the Proforma Invoice (PI for short), which is equivalent to the preliminary version of the contract and contains key information such as price, quantity, product specifications, and so on.

When confirming this invoice, be sure to double-check all the details to avoid any inconsistencies with the quoted price at the time of formal shipment.

A pro forma invoice is often used as the base document for the final quote and once confirmed, the price and terms are not subject to change. It provides a specific price and transaction details for both you and the supplier.

Proforma invoices are also required when you are in the process of import/export customs clearance. So make sure that the order amount on the invoice is the same as the amount you paid.

Proforma invoices help to deal with import and export tax issues by clearly setting out all goods, charges and terms of delivery, which can help in calculating duties, VAT etc. Some purchasers offer lower invoice amounts in order to pay less duty, which entails legal risks.

2.Sign confidentiality agreement

If your new product involves patents, design drawings, or other confidential information, signing a Non-Disclosure Agreement (NDA) is necessary before generating collaborations in large quantities. A Non-Disclosure Agreement can effectively protect your trade secrets, preventing the information from leaking and being utilized by competitors.

Non-disclosure agreements need to specify what kind of information needs to be kept confidential. For example, product design drawings, supply chain data, marketing plans, etc. Only information that is defined as confidential is obligated to be kept confidential by the supplier.

Specify the duration of confidentiality of information. Some information may lose its confidentiality after a certain period of time, while some trade secrets may need to be kept confidential permanently. These periods should be stated in the agreement.

Specify in the agreement the consequences of breaching the confidentiality clause, including fines, compensation for damages, etc. This will better bind the supplier to comply with the agreement.

3.Confirm delivery and delivery time

It’s important to clarify delivery times with your suppliers to ensure your goods arrive at a specific time, otherwise it can affect your sales program.

Confirming delivery and lead times and ensuring agreement with your suppliers can avoid production delays, transportation issues, and supply chain disruptions, among other hassles, ensuring that your products reach the market on time and your business plan is executed smoothly.

Before finalizing an order with a supplier, you first need to confirm the production lead time. The length of the production lead time depends on the complexity of the order, the customization needs of the product, and the production capacity of the supplier.

In the case of high-volume orders or customized products, the production lead time may be longer, so it is important to confirm this point in advance.

When confirming the delivery time, you also need to discuss the mode of transportation (e.g., sea, air, rail, etc.) with the supplier, as well as the transit time. Different modes of transportation can affect delivery times.

For example, sea freight usually takes longer than air freight, but costs less. You need to balance the cost and delivery timeframe with your needs.

Determining the delivery location (e.g., port, warehouse, door-to-door, etc.) also has a direct impact on the delivery time. After confirming the mode of transportation, it is important to clarify with the supplier the place of delivery and whether the supplier needs to provide other services, such as unloading, customs clearance, etc., at the time of delivery.

When determining delivery times, take into account Chinese holidays, such as the Chinese New Year and National Day, which can cause delays in production and logistics. Confirm holiday arrangements with suppliers to avoid delays due to holidays.

For example, you are going to purchase a batch of consumer electronics from China. You have negotiated an order with the supplier and specified the delivery terms as FOB Shanghai. You require the supplier to complete production and ship the goods within 30 days of order confirmation. The supplier provides you with a detailed production schedule and transportation plan: the production lead time is 20 days and the transportation time is estimated to be 10 days. In order to ensure delivery before the holidays, you specifically ask the supplier to produce ahead of schedule and start arranging shipment 15 days after order confirmation. In this way, you avoid delivery problems caused by holidays or production delays.

In addition, you require suppliers to provide regular progress reports prior to delivery so that you can keep track of the status of your orders and ensure that delivery times are on schedule. By clearly communicating and confirming delivery and lead times, you ensure that the product will reach its destination on time.

4.Compensation or solution for product defects

Even very specialized suppliers can encounter some problems with product quality defects during the production process. Whether due to damage caused by production or transportation, product defects can lead to customer dissatisfaction, sales delays or other financial losses.

Therefore, clarifying the compensation and solution for product defects and agreeing with the supplier in advance can quickly help you cope with because of quality problems and reduce losses.

If 5% of the products in a bulk order you receive are defective, you may have to deal with these problems at your own expense if a compensation program is not established in advance. By communicating in advance, you can avoid losses by asking your supplier to include a defect compensation clause in the contract, such as making up for it in the next order or offering a discount of a certain amount.

Types of product defects

Appearance defects

Appearance defects usually refer to problems with the surface or appearance of the product, such as scratches, uneven color, deformation, stains, breakage, etc. Such defects often occur during transportation or without strict quality control during production.

Prescription

- Returns and exchanges: If the defect is discovered before delivery, the supplier can be asked to return or exchange the nonconforming product.

- Compensation Discount: If the defect is minor and does not affect the function of the product, you can negotiate for a discount or refund from the supplier.

- Repackaging or repainting: If the damage is minor and the cost of repair is low, you can ask the supplier to repair it or compensate you for the cost of repackaging.

functional defect

A functional defect is when a product does not function or work properly. Examples include electronic products that do not turn on, mechanical parts that do not function properly, and software that malfunctions. These types of defects usually occur during the manufacturing process and can be caused by poor design, material problems or improper assembly.

Solution:

- Product return or exchange: Ask the supplier to provide a return or replacement, especially if the defect affects the normal use of the product.

- Repair or debugging: For those products with low repair costs, you can ask the supplier to repair or debug them.

- Compensation for damages: If the defective product has caused customer complaints or market losses, the supplier can be held liable for the damages.

Size or specification discrepancy

A size or specification discrepancy is when a supplier delivers a product that does not match the requirements of the order. This can be due to production not following the specifications or an error in the supplier’s understanding of the order.

Solution:

- Return or exchange: Ask the supplier to return or exchange the product that does not meet the specifications.

- Modify or adjust: If only an individual product is out of specification, you can ask the supplier to adjust or replace the product to ensure it meets your requirements.

- Reproduce: If there is a problem with the entire batch, you may need to ask the supplier to reproduce and reship the product.

Material issues

Material defects are problems with the raw materials of a product that may result in substandard quality or a shorter service life. Examples include the use of substandard fabrics for clothing or poor quality plastics for home furnishings.

Solution:

- Replacement of materials: Require the supplier to replace the substandard materials and use compliant materials in subsequent production.

- Returns, exchanges or compensation: For products that have been delivered and found to have material problems, you can ask for returns, exchanges or ask the supplier to provide discounts as compensation.

- Reproduction: If the material problem affects mass production, the supplier can be asked to re-produce qualified products.

5. Determine the payment method

Determining the method of payment with your suppliers is a step towards ensuring a smooth transaction. Different payment methods not only affect the flow of funds, but also directly relate to your risk control and cash flow.

Companies doing foreign trade in China usually accept the following payment methods:

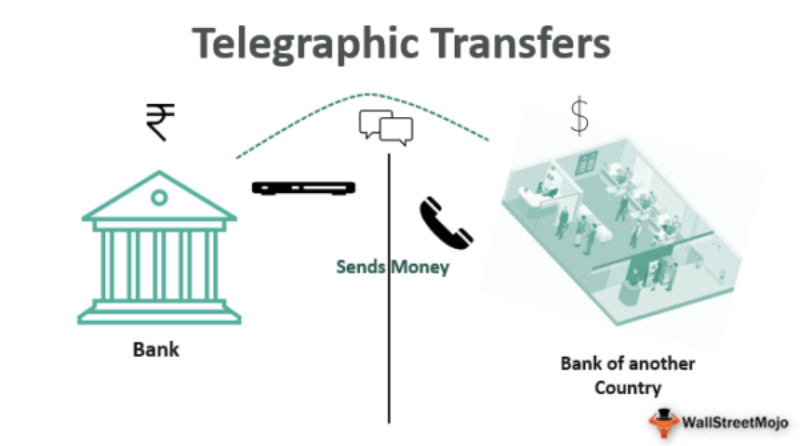

Telegraphic Transfer (T/T)

This is the most common form of payment, where the buyer transfers the money directly to the seller through the bank. Telegraphic transfers are quick and easy and are usually completed within 1-3 business days, but may involve a fee.

Chinese companies usually want to receive payment as soon as possible, so wire transfers have become the most common method of payment.

Letter of credit (L/C)

This payment method provides a guarantee through the bank to ensure that the seller can receive payment for the goods after delivery in accordance with the contract requirements. It is suitable for larger amounts and higher-risk transactions, and can protect the interests of both parties, but the cost of issuing a letter of credit is higher, and the process is more cumbersome. For unfamiliar customers, letters of credit can effectively reduce the risk of transactions.

Chinese companies usually choose the letter of credit payment method in transactions with new customers or unfamiliar markets, because the letter of credit provides bank protection and can effectively avoid the risk of customer default.

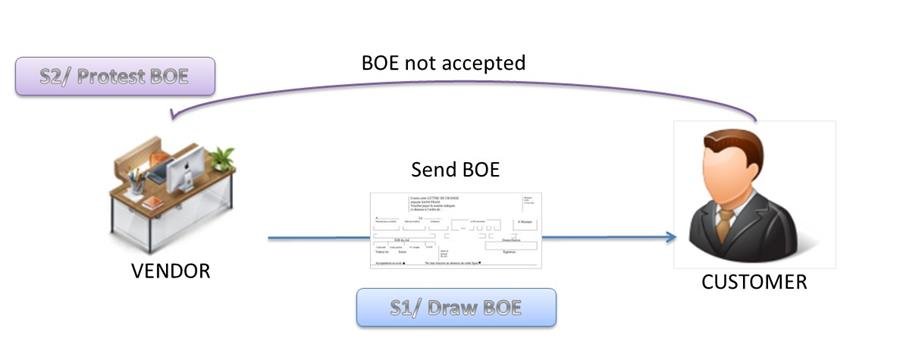

Bills of exchange (D/P, D/A)

Handles the documentation of goods through the bank and the buyer must make payment before he can take delivery of the goods. It is simpler than a letter of credit, but the seller may face some risk if the buyer refuses to pay.

Money orders are an easy and less costly way to pay for orders that do not involve a large transaction amount.

Alipay/WeChat Payment

These payment methods are very popular in China and are particularly suited to small transactions and B2C (business-to-consumer) models. They are easy to use and funds arrive quickly, but are not usually suitable for bulk commodities or long supply relationships.

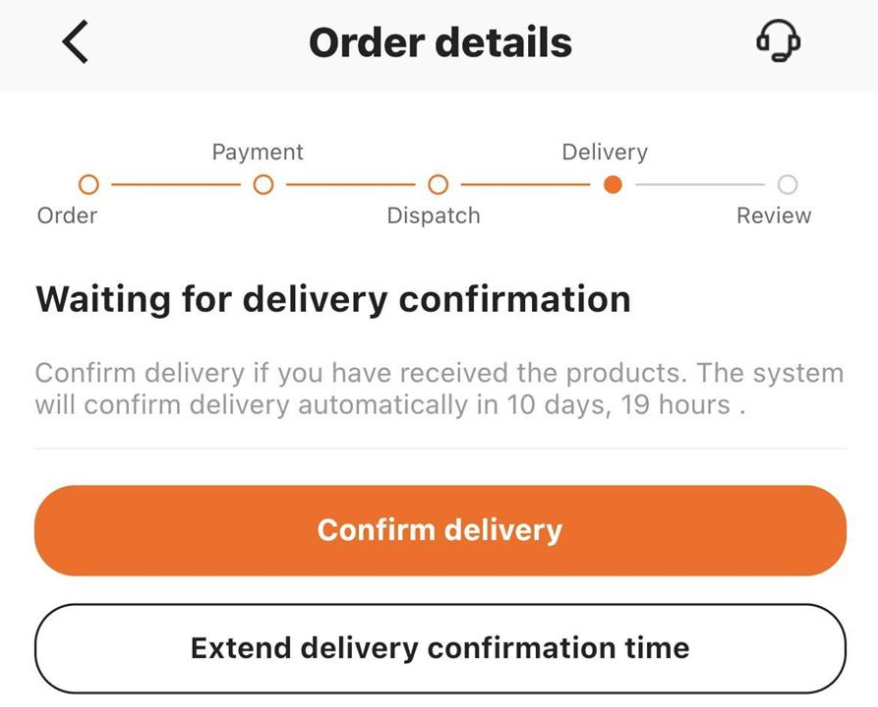

6.Confirm payment terms

Payment terms are not only related to the security of financial flows, but also have a direct impact on the trust and cooperative relationship between the two parties. Clear and reasonable payment terms can help minimize potential risks, protect the interests of both parties and ensure that goods are produced and delivered on time.

Clear payment terms not only help to ensure a smooth transaction, but also effectively minimize risk for both parties. Depending on the type of order and the relationship, suppliers usually offer several common payment methods.

30% deposit and 70% balance before exporting

This payment method is very common in foreign trade transactions, usually used for new customers or first-time cooperation. The buyer needs to pay 30% deposit in advance after signing the contract, and the remaining 70% will be paid before or after the goods are shipped.

For the buyer, paying the deposit ensures that the supplier will produce and ship the goods at the agreed time, while the supplier ensures that the buyer is sincere in placing the order through the deposit. This approach balances the risks for both parties, but the buyer needs to have sufficient financial flow to pay the deposit.

30% deposit, 70% B/L payment

Another common payment method is to pay a 30% deposit and the remaining 70% by way of a bill of lading. This means that the buyer pays the remaining balance to the seller after the goods have been shipped and the bill of lading has been received.

In this way, the buyer is able to receive the bill of lading to confirm that the goods have been shipped, and then complete the final payment, which increases the security of the transaction.

The seller can also ensure that before the bill of lading is handed over to the buyer, part of the payment has been received, reducing the risk. This method is suitable for long-term cooperation between buyers and sellers.

No deposit required, full payment by bill of lading

For partners who have established a long-term relationship of trust, some suppliers even offer the condition of full payment, i.e., the buyer pays the full amount of the goods after receiving the bill of lading.

This approach is very favorable to the buyer, because there is no need to pay a deposit in advance, the flow of funds is more flexible.

As for the seller, it means that trust has been established to a certain extent, and the buyer can confirm the ownership of the goods by virtue of the bill of lading, which reduces the uncertainty of the transaction.

O/A(Open Account)

O/A (Open Account) payments are those that allow the buyer to pay for the goods within a certain period of time after they have been shipped, without having to make any payment in advance.

Typically, O/A payment terms will state that the buyer must pay for the goods within 30, 60, or 90 days, depending on the specific agreement with the supplier.The O/A payment method creates a strong relationship of trust between the buyer and the seller.

Ultimate

I hope this article on things to check with your Chinese suppliers before production helps you to get a cordial cooperation between you and your suppliers. If you have any questions about today’s content, please let me know in the comments below.

Goodcan is a professional agent purchasing company in Yiwu, if you need the best service and offer the most competitive price, please contact us!